Product Introduction

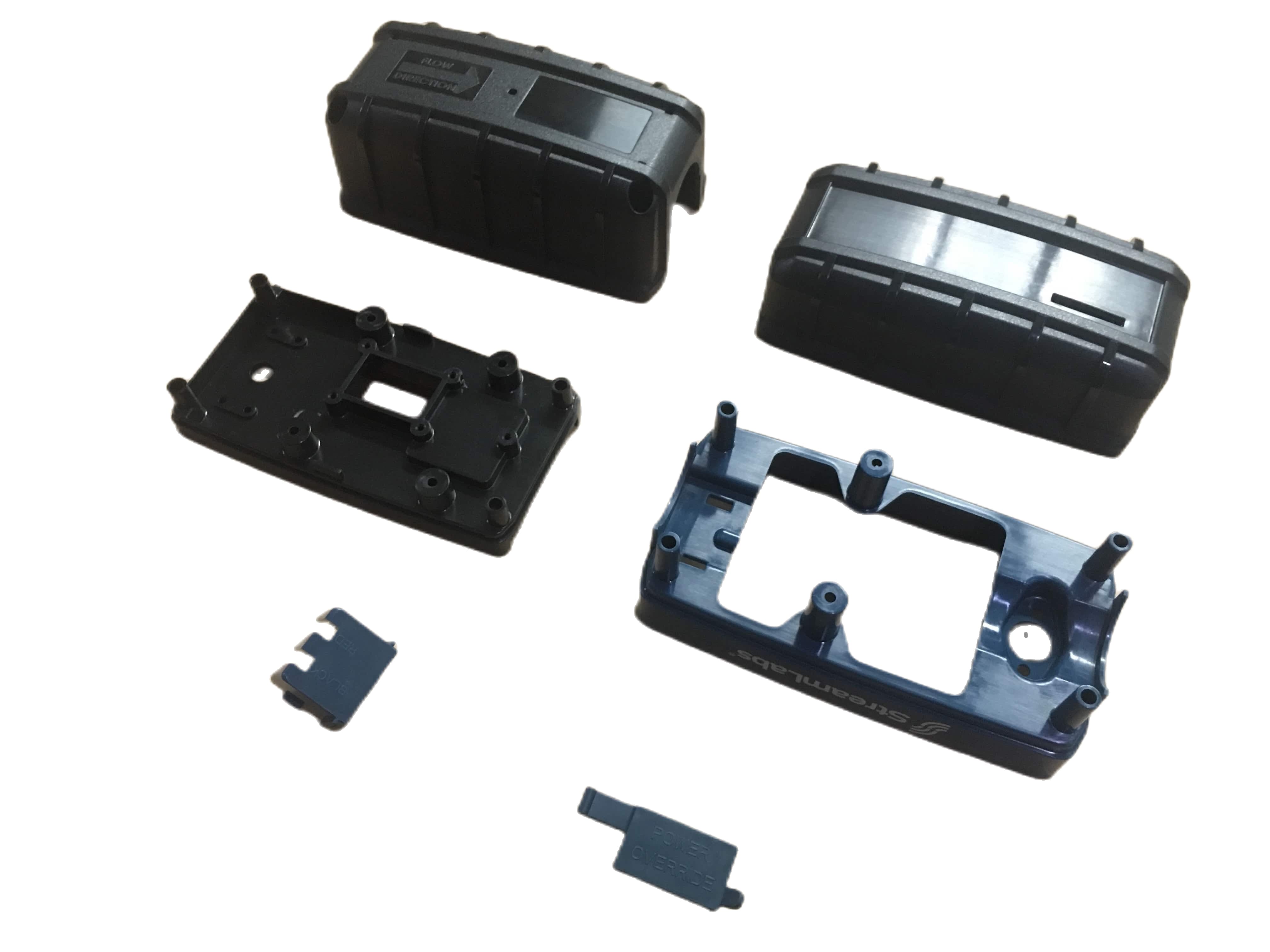

This project was placed to Suntime mould from rapid prototyping to tooling and injection moulding. The housing surface is Mold tech texture and there is silk printing in the middle housing. The parts assembly tolerance is small, and production of plastic tooling & molding are very short. The product is used for Home water monitoring and protection. For this proejct, we provided parts to Australia, USA and Flextronics Mexico.Parameter

| Appliance and Type | Home water monitoring and protection | |||||

| Part name | Top Housing and Bottom Housing/Top Cap and Bottom Cap/9V Battery BOX & Battery Cap | |||||

| Resin | ABS/ TPE | |||||

| No. of cavity | 1+1/1+1/1+1 | |||||

| Mould Base | LKM S50C | |||||

| Steel of cavity&Core | P20 HRC27-33/P20 HRC27-33 | |||||

| Tool weight | 489KG | |||||

| Tool size | 443X400X510 | |||||

| Press Ton | 60 T, 200T, 160T | |||||

| Mold life | 800000 | |||||

| Injection system | Cold runner mould | |||||

| Cooling system | 30 ℃ | |||||

| Ejection System | Ejector pins | |||||

| Special points | Whole project components, needing perfect mounting and silk printing. | |||||

| Difficulties | assembly tolerance is small and manufacturing lead time is very short. | |||||

| Lead time | 4.5 Weeks | |||||

| Package | Stored in Suntime factory for production | |||||

| Packing items | / | |||||

| Shrinkage | 1.005 | |||||

| Surface finish | MT11020/B-3 | |||||

| Trade terms | FOB Shenzhen | |||||

| Export to | Mexico / USA | |||||

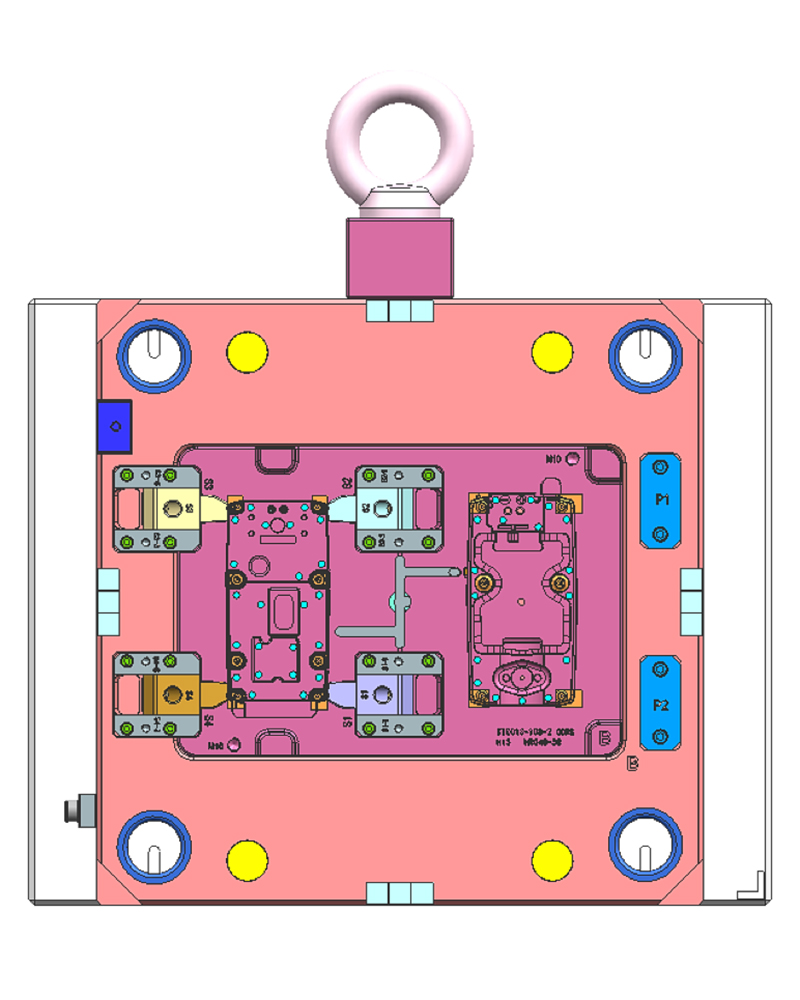

Drawings

For molds staying in China for production, our designers make tool drawings as Chinese production standard. When time is very urgent, we make 3D tool design directly after DFMs. Normally make tools as family moulds to help customers to save tooling cost.

FAQ

Outer housing 3D

Inner housing 3D

3D mould drawing

Other project reference for this customer

Suntime has much experience of whole package tool making and moulding. Below is one of the project with PPSU material. The moulds are high temperature moulds, temperature reach to 160 degree, cooling by oil. They are rings for water pipe products.

Customer's testimonial

Good Morning Selena and Gevin, I would first like to say, thank you very much on producing the samples and parts for this project. They look very good. I would also like to pass on Alex’s message on how happy he was with the quick turn around on the tooling project and samples, also the thanks on making this happen. We are all grateful and appreciative on all the work done to this project. Please pass on our message of a job well done to the rest of your team.——Edmund.T