Product Introduction

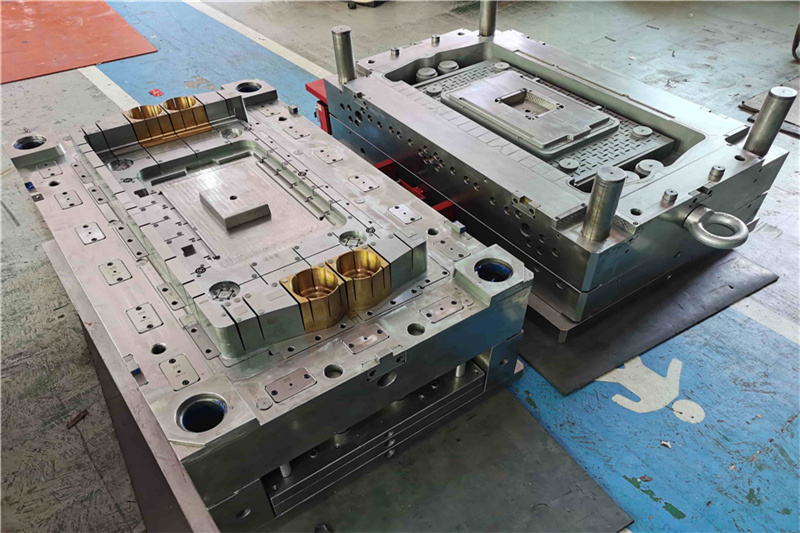

This product is one of the components for gold cart. Part is big and have deep ribs, need to do well to control the warpage. We used Becu inserts for cooling in deep rib area. Besides on controlling warpage, the balance filling is also very important. Suntime has experience designers and engineers, their rich working experience for these kind of big parts guaranteed the high quality and timely delivery.Parameter

| Appliance and Type | Component for golf cart | |||||

| Part name | SEAT KIT BASE | |||||

| Resin | PP-GF30 | |||||

| No. of cavity | 1 Cavity | |||||

| Mould Base | LKM S50C | |||||

| Steel of cavity&Core | 738 H HRC33-36/738 H HRC33-36 | |||||

| Tool weight | 5943KG | |||||

| Tool size | 1610 X 1070 X 867 | |||||

| Press Ton | 1200T | |||||

| Mold life | 300000 | |||||

| Injection system | 6pcs valve hot tips | |||||

| Cooling system | temperature 50 ℃ | |||||

| Ejection System | stripper plate and ejection pins | |||||

| Special points | Big part, deep rib and high request of cooling | |||||

| Difficulties | Need to control well for deformation, used Becu inserts for cooling and control well for filling. | |||||

| Lead time | 5.5 weeks | |||||

| Package | Anti-rust Paper and film, little anti-rust oil and plywood box | |||||

| Packing items | Certification of steel, final 2D & 3D tool design, hot runner document, spare parts and electrodes… | |||||

| Shrinkage | 1.005 | |||||

| Surface finish | MT1055-2/B-2 | |||||

| Trade terms | FOB Shenzhen | |||||

| Export to | USA | |||||

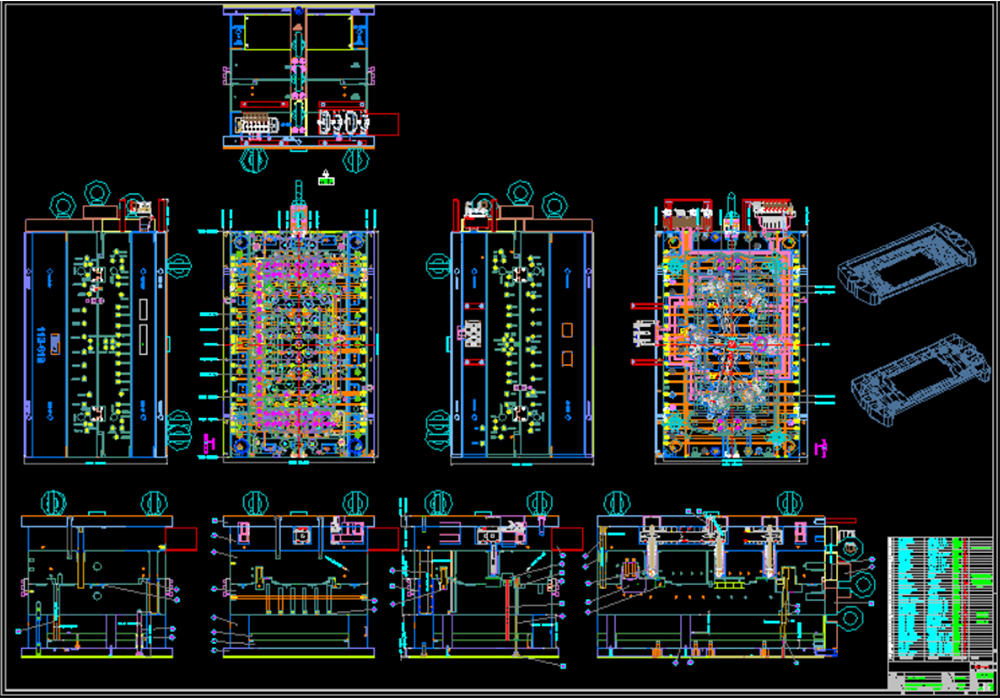

Drawings

Suntime has very effective mold designers. For DFM, it can be finished within 1~2 days, mold flow / 2D layout within 2~4 days And 3D within 3~5 days depending on mold complexity.

DFM Analysis

FAQ

Mold flow

2D layout

3D mould design

About Shipping

Before shipping, we double check the mold with a specification checking list to make sure every details are correct as customers' requests. Take photos for all components and the mold. We use anti-rust paper /vacuum packing and plywood box to pack the mould In the box, there are final data of 2D & 3D mold design, steel & heat treatment certifications, electrodes, spare parts, hot runner usage manual and so on. After Service:Any complaints will be replied within 24 hours and components are provided for free within warranty time. Technical support for Whole life.

Other big part projects reference

Our biggest mold reach to 13 ton and 2.1 meter height for Toyota RAV4 side step. Our crane is 10 Ton which can make around 20 ton big tools. 40% of our molds are for Automotive, our price and quality bring you more value.